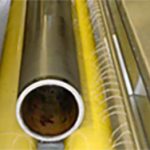

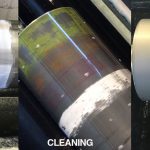

The OptiClean cleaning machine has been especially developed for high line anilox rolls. Partly due to the special rubber roll construction, anilox rolls up to 1.000 L/cm can be cleaned smoothly.

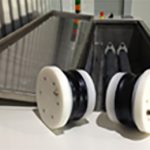

The OptiClean machine functions by heating 2 rotating rubber rolls. This creates a kind of channel with heated liquid that remains in constant contact with the pollution on the anilox roll. As a result, the OptiClean has an optimal cleaning result in contrast to machines where the polluted rolls are positioned on wheels and the cleaning agent therefore directly falls off the roll.

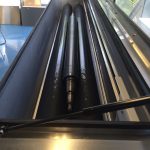

The Opticlean is very flexible in terms of length and diameter. The OptiClean can clean anilox rolls in all desired sizes, lengths and diameters. You can even combine different lengths and diameters in the machine.

In addition, even the largest sleeves can be closed by means of het new “sleeve closing device”. The adapters will automatically expand due to the use of compressed air.

It takes approximately 20 minutes to clean the anilox rolls with the OptiClean machine. The anilox roll rotates between 2 rotating rubber rolls in which the heated cleaning agent is positioned. During the cleaning process, the anilox roll remains in contact with the cleaning liquid and the rubber rolls. Thanks to the optimum hardness (shore) of the rubber rolls, the heated cleaning agent is “rubbed” into the cells of the anilox roll. This results into an optimal cleaning.