The AL1500 is a high-tech anilox roll cleaning machine, developed by experienced anilox roll experts. The machine cleans the anilox rolls and –sleeves by means of a laser, in the safest possible way, without damaging the cell structure.

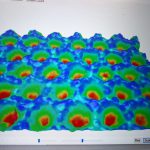

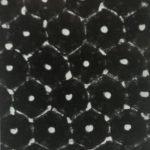

The AL1500 cleaning machine uses the latest MOPA laser technique with adjustable pulse frequency and pulse time. As a result, the laser intensity can be set and will thus cause no damage to the cell structure. In addition, the AL 1500 has an automatic follow focus system for reproducible results, so that the optimal cleaning result is always achieved.

The AL1500 Offline Laser smoothly cleans anilox rolls and –sleeves up to a line of 1.000 L/cm. Special software checks the laser continuously, so that the anilox rolls are always optimally and safely cleaned.

The cleaning process for a sleeve of 1380 mm and a diameter of Ø159,90 takes approximately 30 minutes. A timer in the display shows you, how long the cleaning process still takes.

Endurance tests have shown, that the AL1500 Offline Laser can clean the anilox rolls infinitely without damaging the rolls. This extends the lifespan of the anilox rolls, while being able to produce with controlled parameters. In addition, the machine stores the roll numbers in the system, so you can exactly see how often en when a roll has been cleaned. Finally, the pollution is collected high-end filter system and produces minimal waste.